Engineering Services

Transducer Certification as a Service

Misc System Developments

Application Development

Products supporting Inspection

Transducer Certification as a Service

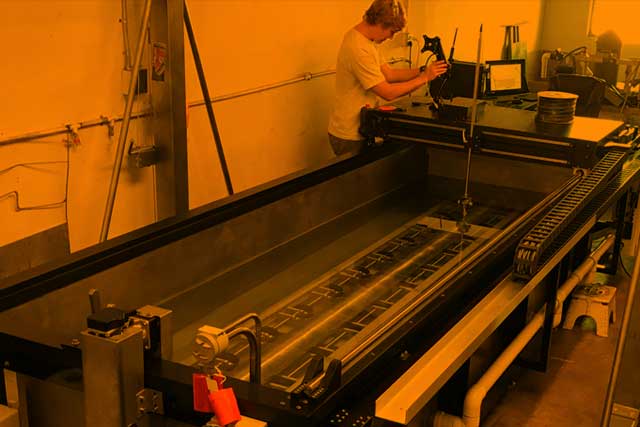

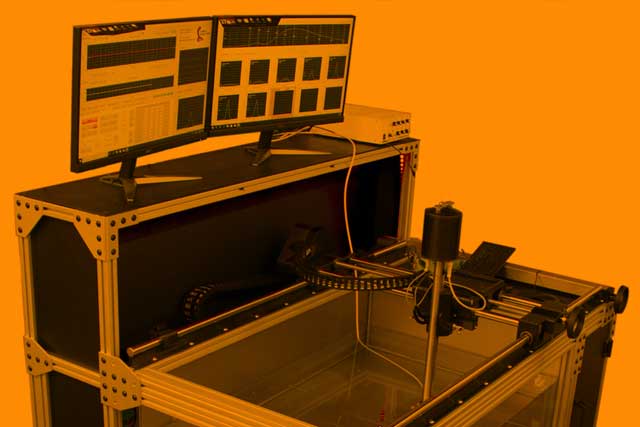

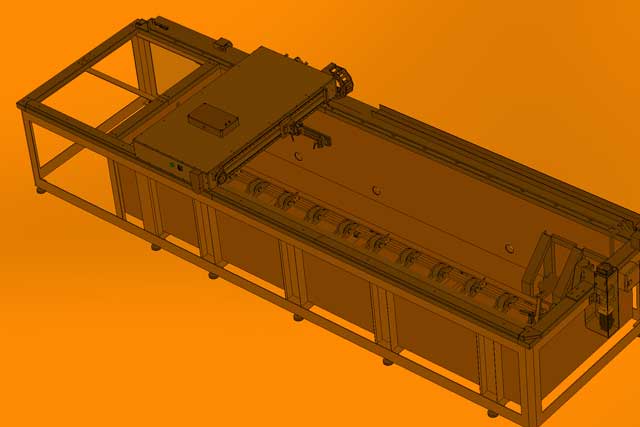

With over 45 years of experience in Ultrasonic Transducer Design, Development and Manufacturing experience, Cobra Scientific turns our vast knowledge and techniques to offer Ultrasonic Transducer Certification as a service incorporating our fully in-house developed DocSys-3, (Patent Pending) Fully Autonomous Ultrasonic Transducer Certification Station offering a 1GHz Digitizer for optimal echo capture fidelity.

Over our many years we’ve seen, tested and worked with and seen “all kinds” of Ultrasonic Probes in all sorts of conditions that probably should have been reviewed, repaired or discarded. In particular, if any of your Immersion Transducer faces are not smooth or appear to have any bubble looking epoxy, chances are high they need review.

Certifications defined meet ASTM e1065 or virtually any Customer specific style and, we proud the system produces results Approved by GE to P3TF24.

If your requirements are higher in volume or require more regular certification to maintain customer guidelines, the system is available for purchase. Please See our DocSys-3 product page or contact us.

Products supporting ongoing Inspection Requirements

Cobra Scientific, LLC offers a line of products complimenting the Ultrasonic NDT Inspection arena. Products including Autonomous Transducer Certifications, fully powered underwater Gimbal-Gimbal Manipulators, Lab Tank Swivel-Gimbal-Z and mini-manual manipulators. We also offer a host of adaptive fixtures built to customer specifications.

- Manual Swivel-Gimbal Powered with Z-axis: The Manual Swivel-Gimbal manipulator offers the user out-of-the-water manual positioning of the transducer in both rotational about the up-tube axis or Swivel axis as well as a gimbal axis pointing the probe up and down to the bottom of the tank. Learn more >>

- Powered Gimbal-Gimbal Ultrasonic Manipulator: The MGG-BL-220 Triple Sealed, Powered Underwater Manipulator represents the latest in State-of-the-Art Design and Power. Learn more >>

- MiniMan 2 – Manual Gimbal-Gimbal Ultrasonic Manipulator: The MiniMAN-2 is a Search Tube mountable miniature Gimbal-Gimbal Manipulator offering a very smooth motion on both axis. Learn more >>

Engineering Services

Cobra Scientific offers a very unique approach to your inspection requirements with several of our Team offering you our individual experience levels reaching back to 1975… We’ve seen a lot in our time. Our significant previous experience in the design and development and manufacture of Ultrasonic Transducers and Instrumentation make us uniquely positioned to actually know how to press the limits of what is possible.

Working with many of today’s prime manufacturers we are well familiar with many of the exotic alloy materials as well as varied composite materials and structures. We’ve been involved on the development of wind turbine blade transducer fixturing and concept development for scanners to defining and refining turbine blade inspection techniques. From manual inspection to full body automated inspection

With this, we can work to understand your needs and offer the most Practical, Integrated, and Cost-Effective solution.

Given this long-term experience as industry manufacturers, we are also very aware of equipment solutions currently available and, partnering with most providers, we can offer the best End-to-End Solution. In a phrase, we are agnostic and work to develop the BEST solution for your requirements.

We incorporate solid modeling very early on in a project and, In order to provide the fastest turn for review or in some cases for the final assembly we maintain a bank of 6 varied 3D printers incorporating SLA for precising modeling and reproduction, high resolution FDM for larger components and Carbon Fiber Reinforced Nylon providing work ready parts.

We also have several CNC mills and lathes as well as their manual counterparts to always be in control of critical components or component lead times, streamlining the manufacturing process.

We frequently work under NDA and ITAR compliance as well as Cyber Safe outlines.

We Offer:

- Custom Engineered Solutions for Non Destructive Testing (NDT)

- Application Development from Concept, Design to Manufacture

- Inspection Systems Engineered for your Specific Requirements ranging from simple manual hand-held fixtures to semi-automated to full robotic autonomous inspection systems.

- Specializing in Ultrasonic Flaw Detection and Thickness gauging applications as well as Eddy Current Inspection Systems.

- Full Motion Control and Data Acquisition along with Custom Analysis capabilities, Custom Engineered for your requirements

Miscellaneous System Developments and Re-Manufacture

Cobra Scientific works with you and your specific requirement to provide a practical, cost effective means to your inspection requirements. We have worked with prominent Space, Military, renewable energy and commercial companies in the development of new and novel inspection techniques.

In addition, we have re-manufactured and in some cases re-purposed abandoned, skeleton system components, bringing them to a whole new level of performance and, saving significant costs.

We can review an application and develop custom scanners to suit your requirements. We’ve designed scanners ip to 15’ long for wind turbine blades and others 20’ tall performing inspection on COPV’s Carbon Fiber Overwrapped Pressure Vessels, High resolution fuselage scanners and more. We can work to develop the concept or, work with and towards a development incorporating your thoughts.

Other scanners or scan encoding devices include designs such as manual single axis to dual axis manual and further to semi-automated X-Y scanners controlled by an acquiring instrument or PC.

Please call to discuss your requirement or contact us through this page.

Application Development from Concept, Design to Manufacture

Our team offers decades of experience in the development of Ultrasonic Non-Destructive testing solutions and can work hand in hand with your team to help develop cost effective solutions from simple ultrasonic transducer fixtures to the design and integration of complex motion and data acquisition and automated analysis based inspection requirement.

How can we help you? Contact us today.